This article originally appeared in the May/June 2013 issue of Zymurgy Magazine

By Drew Beechum

By Drew Beechum

Brewsters and brewers! Isn’t it time you stood tall? Isn’t it time you put away those wobbly, haphazard ziggurats of hastily assembled supports? Don’t you want to look and feel like a “real” brewer with gleaming metal assuring you that your pots of scalding liquid aren’t going to crash about your ears anytime soon?

And how would you like to do it with all the mechanical skill of a box tortoise? Then step right up to Brewgyver’s Traveling Show of Wonder Materials for your answer!

I’ve written before about my complete lack of mechanical skill. I consider replacing a broken switch plate a notable task worthy of trumpeted fanfare. Kent Fletcher (“Fletch”), the Brewgyver of the Maltose Falcons, on the other hand, doesn’t consider it a brew day until something’s been disassembled and reassembled and possibly once more just for good measure. Fortunately, Fletch forgives me my shortcomings and helps me out.

Like many of you, I’ve stared longingly at the highly polished turnkey systems that sit at the high end of the market, but until the day that someone decides I’m a great guy who deserves a free system, the lust will have to remain in my heart. Also, let’s face it, to many homebrewers you’re cheating if you’re buying instead of building.

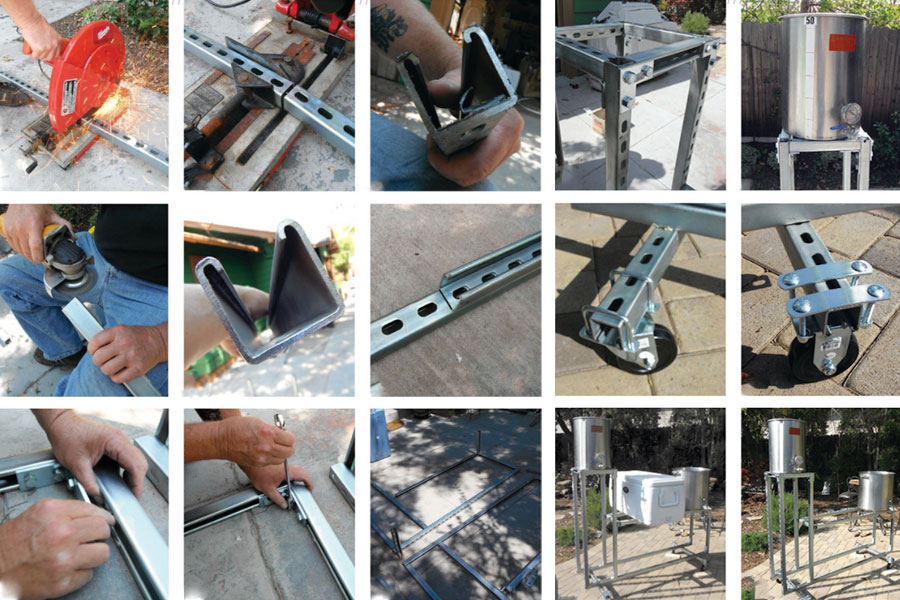

STANDING CONCERNS

The primary concerns of any would-be stand builder are stability and weight management. Water is dense and heavy to the tune of 8.3 pounds per gallon. That means you’re supporting roughly 120 pounds of liquid weight…

Access premium member content for $4.99/month. Join Now

Access premium member content for $4.99/month

Join for $4.99Already a member? Login here